Coffee cultivation and trade began in the Arabian Peninsula. Until the 15th century, coffee was grown in present-day Yemen and by the 16th century it was known in Persia, Egypt, Syria and Turkey. European travelers returned from the east with stories about the unusual black drink, “Arab wine”, as it was also called. At first, it was viewed with suspicion, and the clergy in Venice had to ask the consent of Pope Clement VIII to use it.

Who discovered coffee?

The best-known legend about coffee says it was discovered by chance by an Ethiopian pastor named Kaldi, in around 500 AD. He noticed that after eating the fruit of a certain bush, his goats became so energetic that they couldn’t sleep at night. Kaldi told this to the abbot of the local monastery who decided that these “berries” were unclean and had them burned.

The berries released a pleasant and intense aroma that surprised the abbot. He drank an infusion of roasted beans and noticed that he became much more alert during the long hours of evening prayer. The news spread quickly, and coffee began its journey around the world.

The journey of coffee

In 1645, the first coffee shop opened in Venice. At around the same time, coffee reaches England, Austria, France, Germany, and the Netherlands. Beginning with 1700, European missionaries, pilgrims, merchants, and sailors brought coffee with them to the colonies and to the Americas. By the end of the 18th century, coffee had become one of the most profitable crops in the world. After oil, coffee is the most sought after commodity in the world to this day, and the second-most traded good on the stock exchange.

Cultivation

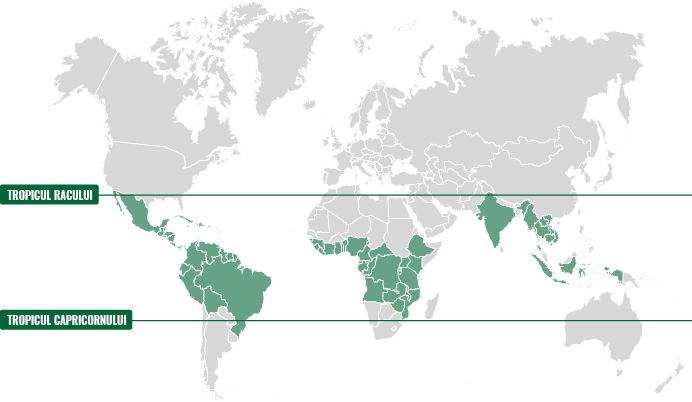

Coffee is grown in over 80 countries around the world, with the largest producers being Brazil, Vietnam, Colombia, Indonesia, and Ethiopia.

What is coffee?

In 1737, Swedish botanist Linnaeus included the plant in the genus Coffeea, part of the Rubiaceae family. Although there are many species belonging to the genus Coffea, from the consumer’s point of view, only two species are important:

Coffea Arabica and Coffea Canephora (or Robusta).

Coffee is an evergreen shrub that grows in the equatorial areas between the two tropics: Cancer and Capricorn.

The coffee bean we know is the seed of a red or yellowish fruit called a cherry, in which there are two beans placed face to face on the flat side. They are covered by a thin and delicate shell (called silverskin), covered by a hard membrane (called parchment) which in turn is surrounded by a sweet gelatinous layer.

Arabica

Today, 2/3 of the world’s coffee production is Arabica, with the largest producers being Brazil and Colombia. It is more expensive and finer than Robusta coffee.

Caracteristici

- It grows at altitudes between 800-2000 meters, in volcanic, fertile soils

- 15-24C temperatures, not frost-resistant

- Caffeine content averages 1.2%

- The green bean is less bulging, has an irregular crack, which in washed Arabica turns golden when fried

- It has a bluish-green color and an oval, elongated shape

- The fruit reaches maturity in 6-8 months

- 44 chromosomes

- Pleasant bitter taste, distinctive acidity, and aromas from chocolate to fruity floral

Robusta

Cultivation of robusta started in West Africa and Southwest Asia. This strain is more resistant to diseases, has higher productivity, and a lower price than Arabica.

Caracteristici

- It grows from sea level to 800 meters, in warm areas with less fertile soil

- 24-30 C temperatures

- Caffeine content averages 2.3%

- Darker, rounder bean with a straight crack, which is dark when fried

- It has an uneven, greenish-brown color

- The fruit reaches maturity in 9-11 months

- 22 chromosomes

- Raw bitter taste, intense full-body, spicy, earthy, wood, chocolate aromas

The 3 Steps of processing

green coffee

Step 1

Harvest

Manual – specific to Arabica grains. The fruits can be found in different stages of development on the same branch at the same time, from flower to ripe cherry. Harvesters only choose the right ripe grains, because the overripe ones will have a fermented taste, and the unripe ones will have an unpleasant and astringent green pea taste. A single defective bean can spoil the taste of a cup of coffee. Manual harvesting is also practiced on farms in mountainous, steep areas, where access to harvesting machines is impossible.

By shaking – It is a typical method for Robusta and preferred in Brazil, for Arabica varieties. It is possible in large, straight areas, where trees are grown in rows. It is a much faster and cheaper method of collection. The machines harvest all the cherries, both ripe and unripe, with branches, leaves. Subsequently, the harvest goes through a process of selection and removal of foreign bodies.

A picker collects between 50-100 kg of cherries per day. Of these, only 20% are valid grains (seeds), the rest being shells and husks. Therefore, a harvester collects on average 10 – 20Kg per day, or a 60 kg bag per week. Harvesting is done every 2 weeks. It is estimated that the cost of harvesting represents half the annual cost of a coffee plantation.

Step 2

Cherry processing

Cherry processing should begin as soon as possible after harvest, to prevent damage. Depending on the location and resources, coffee can be processed in two ways:

The wet or washing method only applies to hand-picked cherries. After the red coating is mechanically removed, the beans in the parchment are placed in tanks with water to remove the pulp, thus obtaining a coffee with a higher aromatic profile. The grains in the parchment are dried in the sun on clean surfaces and turned daily for about 28 days, until their humidity reaches 11%, after which they are ready for storage.

The dry or natural method consists in drying the cherries in the sun for 3-4 weeks, after which mills are used that remove the dry skin and extract the green grain. It is a cheaper, simpler method, used in Robusta and, traditionally, in Brazil and Ethiopia.

Step 3

Sorting, storage and export

The parchment from the wet-processed beans will be removed only right before export for better storage and preservation of coffee quality.

Green beans are sorted and classified according to size, shape, type (Washed or mild Arabica, Natural Arabica, Robusta, Washed Robusta), number of imperfections, density, time of harvest, and taste characteristics.

Defective grains are removed. In many countries, this process is done both mechanically and manually, ensuring that only the best quality coffee beans are exported. Generally, coffee is sold in 60 kg bags.

The final destination

Cafea Fortuna manufacturing plant

The Cafea Fortuna brand has over 25 years of experience in coffee processing. Dedicated employees and innovative technology are the two most important components on which we have built our brand and on which we rely every day to ensure superior product quality.

See products

The production process is divided into several stages: tasting and selection of green coffee in the laboratory, transport to the factory, storage, roasting, blending according to our recipe, grinding, packaging and storing of the finished product. The whole process of transport, roasting and primary packaging is an automated one, supervised by our specialized personnel.

The Laboratory

Fortuna Coffee specialists have the awesome responsibility of choosing, defining and permanently checking the quality of the purchased green coffee. The primary criterion that guides and differentiates Cafea Fortuna is the taste of coffee.

The incoming batches are analyzed both physically and organoleptically. The tasting process focuses on the impressions from the beginning and the end, the flavor profile, the acidity level, the body, the balance, and identifies and rejects imperfect beans.

The journey to the Cafea Fortuna factory can take up to three months. To maintain the quality of the grains, we opt to transport it in double bags that are placed in containers lined with bags that absorb moisture. Even so, the coffee must be tested on arrival, and several more times before it goes into the blend. Because the taste of coffee is so precious, we take care of it throughout production.

Green coffee storage

Upon entering the Cafea Fortuna factory, the raw material arrives directly in green coffee storage. Representative samples are taken from the new batch and sent for testing. While here, the coffee is processed to remove foreign bodies: threads, sticks, cherries, broken beans, after which, it is transferred to the green coffee silo.

Roasting

Roasting coffee is, at the same time, an art and a science. Green coffee has no coffee flavor at all. But during the process of roasting, it develops between 800 and 1000 different flavoring substances, changes color, loses between 10-20% of weight and increases in volume.

Roasting is a complex chemical process that determines the aroma of coffee, the body and the level of acidity. Depending on the roasting parameters, these components can be created, balanced or destroyed. Cafea Fortuna pays special attention to this process. Through the experience gained, we developed our own roasting recipe that gives uniqueness to each blend.

To highlight all the flavors, we chose to roast the coffee lightly. If roasted too lightly, the aroma would be undeveloped, more raw. If roasted more intensely, the fruity-floral aromas would disappear and the coffee would become more bitter. After removing it from the oven, the coffee is cooled and stored in the roasted coffee silo.

When roasting, the volume of the coffee bean increases by up to 60%.

It expands due to the pressure of the heated gases that form inside the grain.

Recipe

The blending of coffee origins is essential in creating a quality taste. For example, Arabica blends are sweeter and more fragrant, while Robusta blends are more full-bodied and intense. After roasting, the various origins of coffee are mixed in controlled quantities, according to the standard recipe, carefully kept in the laboratory of Fortuna Coffee.

Coffees of different origins have distinct flavors and characteristics. In addition, as with other crops (grapes, for example), the taste of berries of the same variety may vary from one harvest to another, depending on the climate conditions. As a result, our great challenge is to ensure the same taste and the same quality of products year in, year out.

Packaging

In order to keep the aroma profile intact for as long as possible, the coffee is packaged in a low-oxygen modified atmosphere. The coffee beans are packed immediately after roasting, in special bags with one-way valves that allow the elimination of roasting gases, without letting in oxygen.

For the ground version, the coffee beans are transported to the mill. Here it will be processed according to an optimal granulation: not very fine, in order to be filter-compatible, but not too big to release all the flavors from the grains.

After grinding, the coffee is stored for a long time in special bunkers to release gases that would otherwise inflate the package, but not more, so as not to lose its flavor. Each step is carefully monitored by specialists assisted by modern equipment.

The ground coffee is packed in 100g sachets or vacuumed in 250g and 500g packs.

Delivery

Cafea Fortuna products are ready to deliver cross-country and beyond.